PROFIMAT for gaskets producers

PROFIMAT is designed to revolutionize gasket quality control processes. Our system utilizes state-of-the-art imaging technology to meticulously inspect gaskets with unparalleled precision and efficiency.

Equipped with advanced machine learning algorithms, our system can detect even the slightest imperfections, ensuring that every gasket meets the highest standards of quality and reliability.

Profimat Use cases

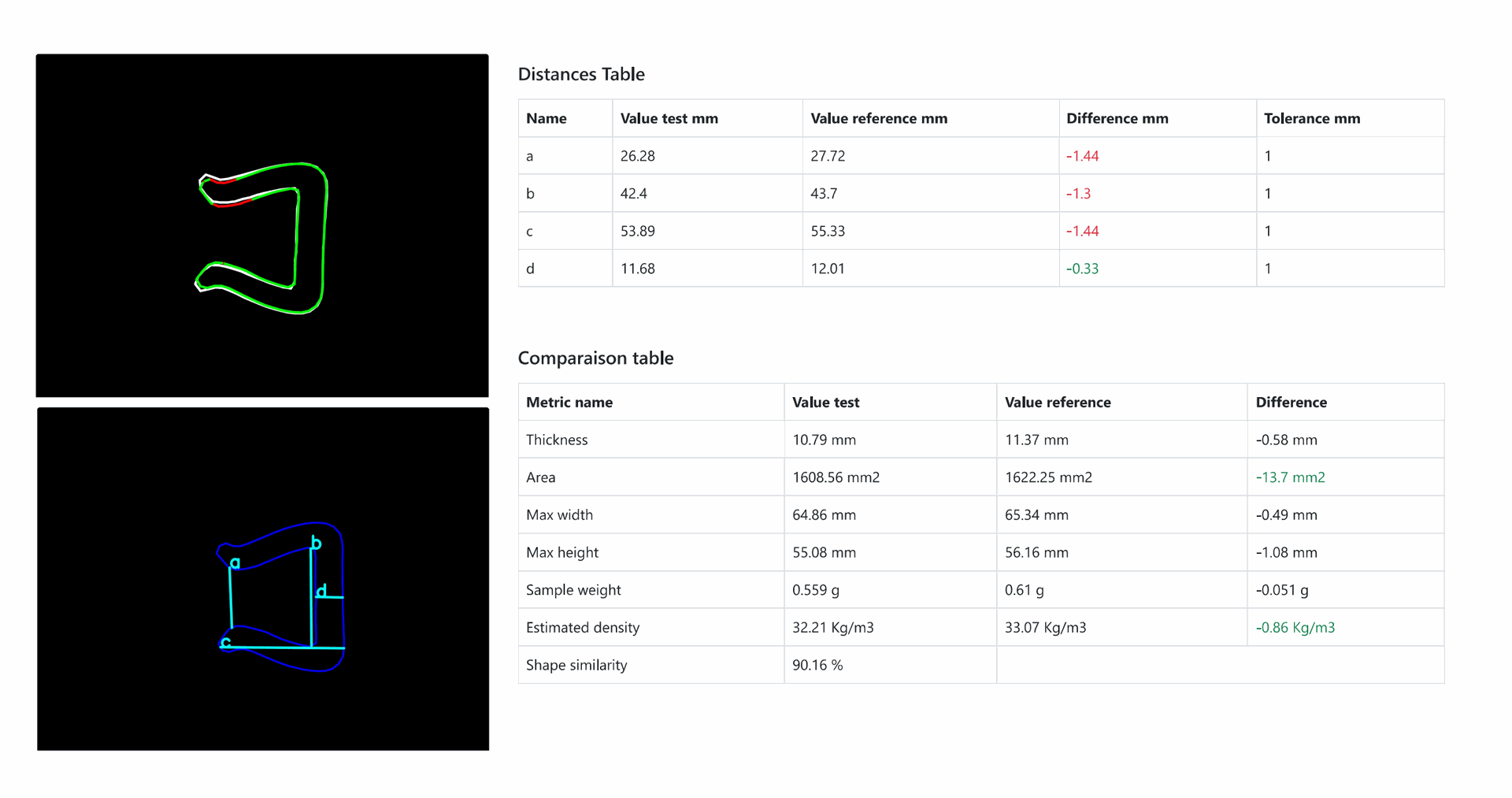

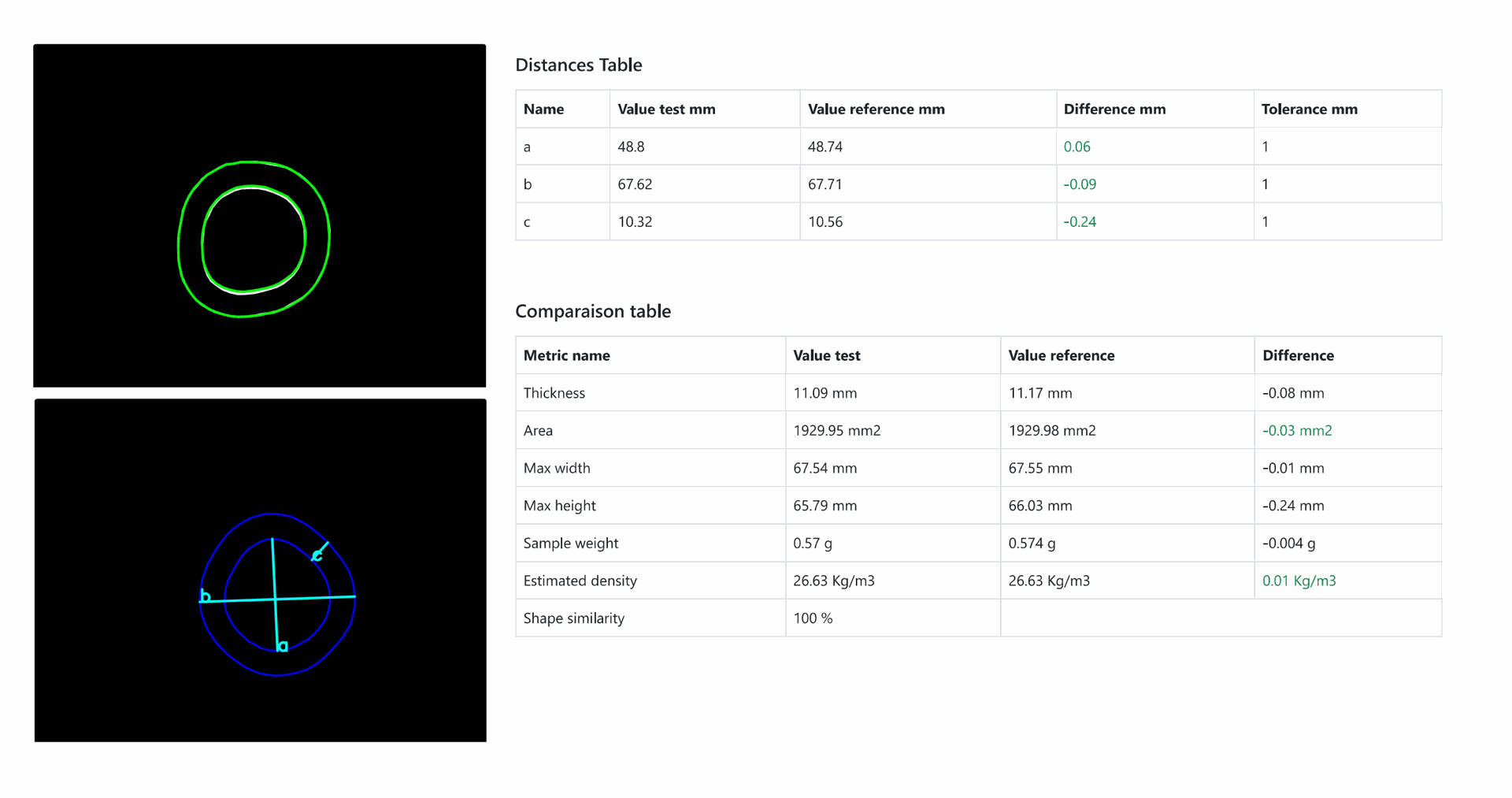

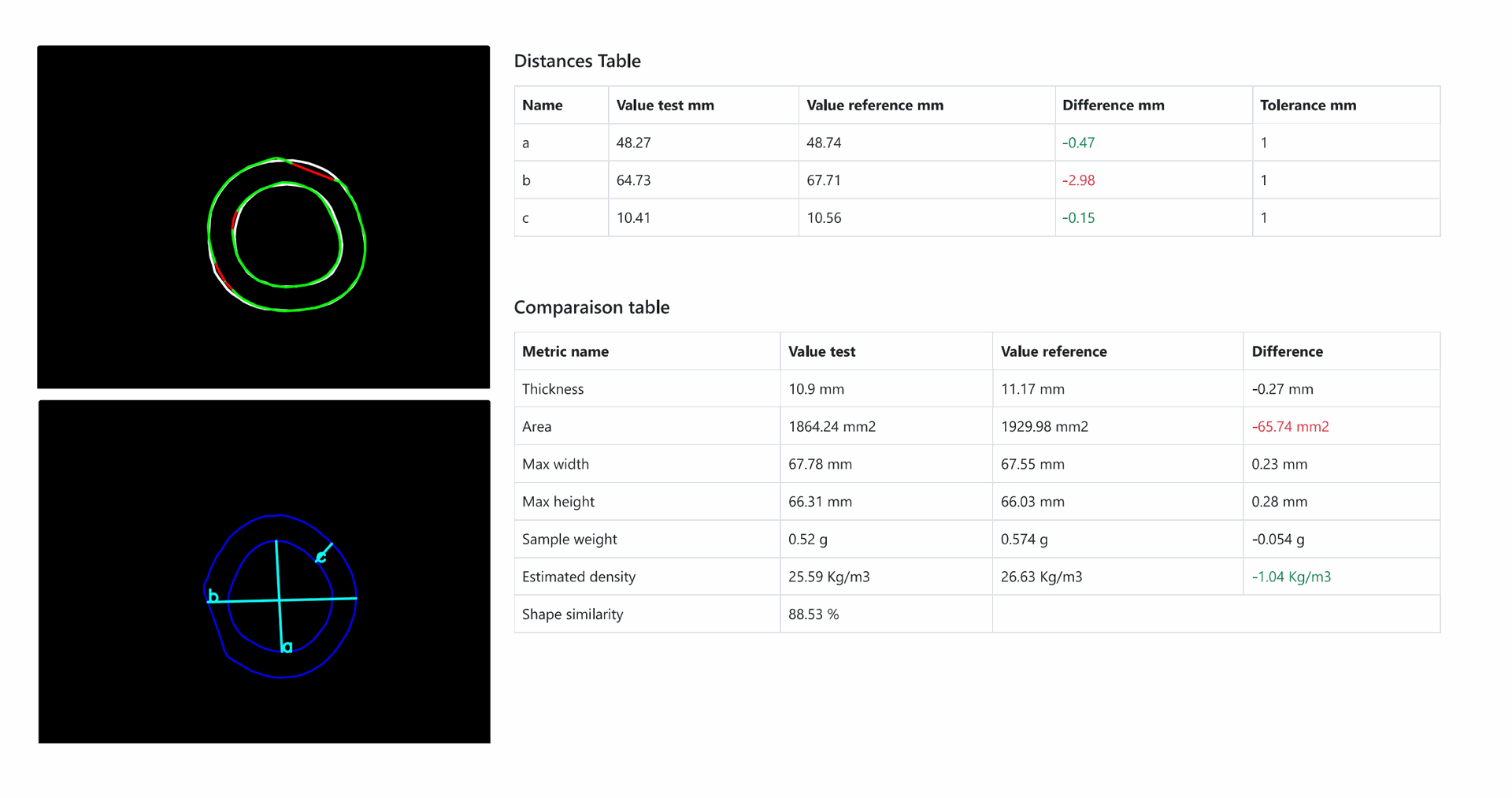

Rubber

Simply position the samples inside the PROFIMAT, and initiate the inspection process. The system will analyze each seal, identifying defects with precision and efficiency, thereby streamlining production and ensuring consistently high-quality rubber seals.

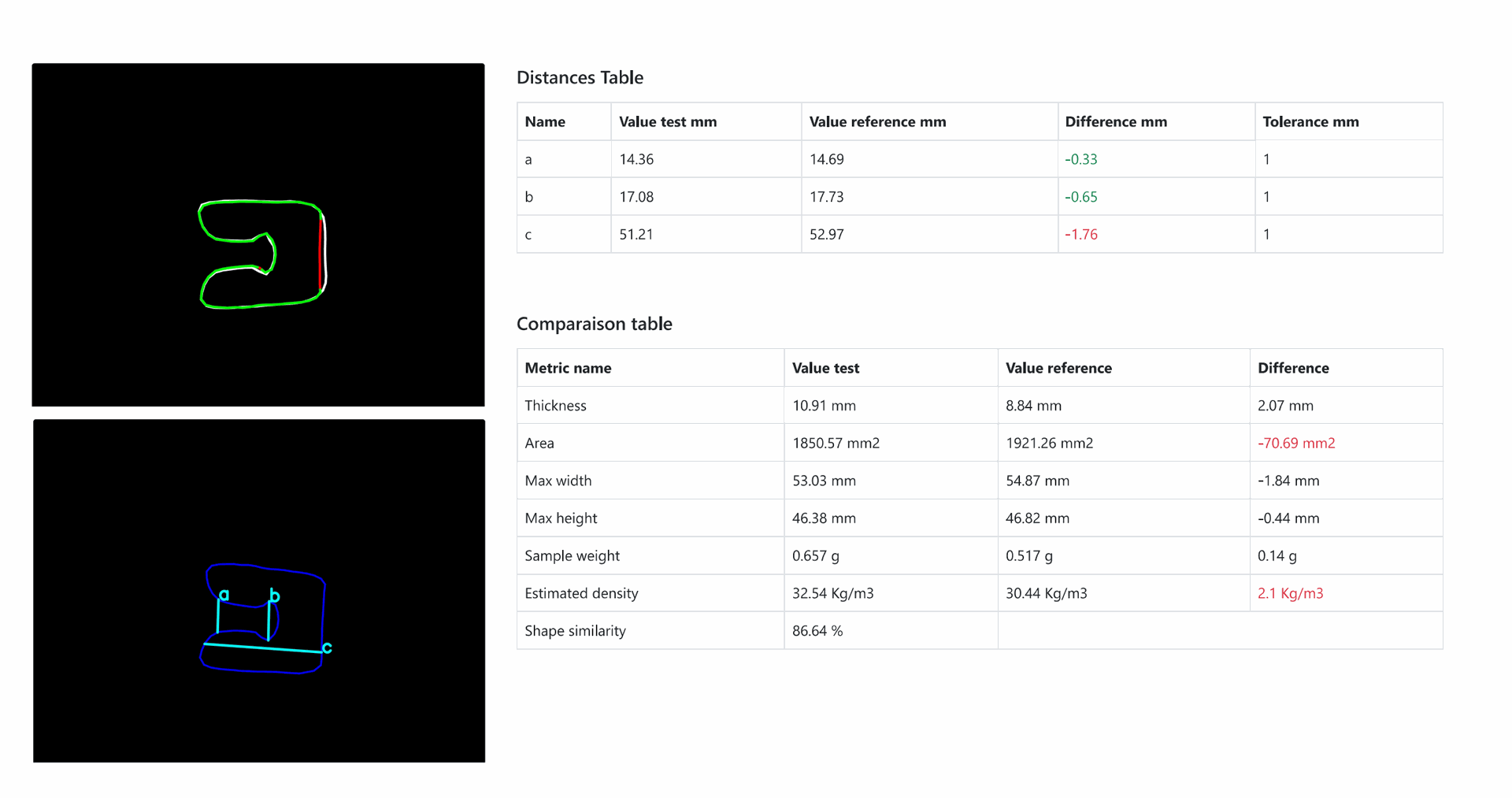

Plastic

For custom plastic extrusion quality control automation, align the extruded plastic within the camera's view and push the start button. It rapidly scans for imperfections, optimizing production by detecting any defects in the extruded plastic.

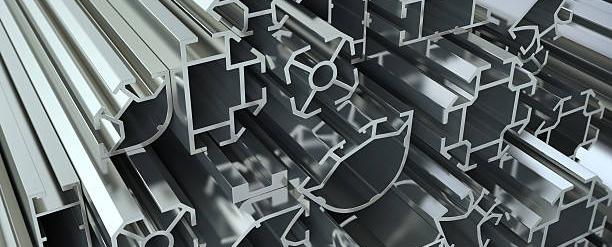

Metal

Position the items to inspect inside the machine and initiate the inspection. The system look for any flaws or irregularities, ensuring that only flawless metal and aluminum components proceed down the production line, enhancing efficiency and product reliability.

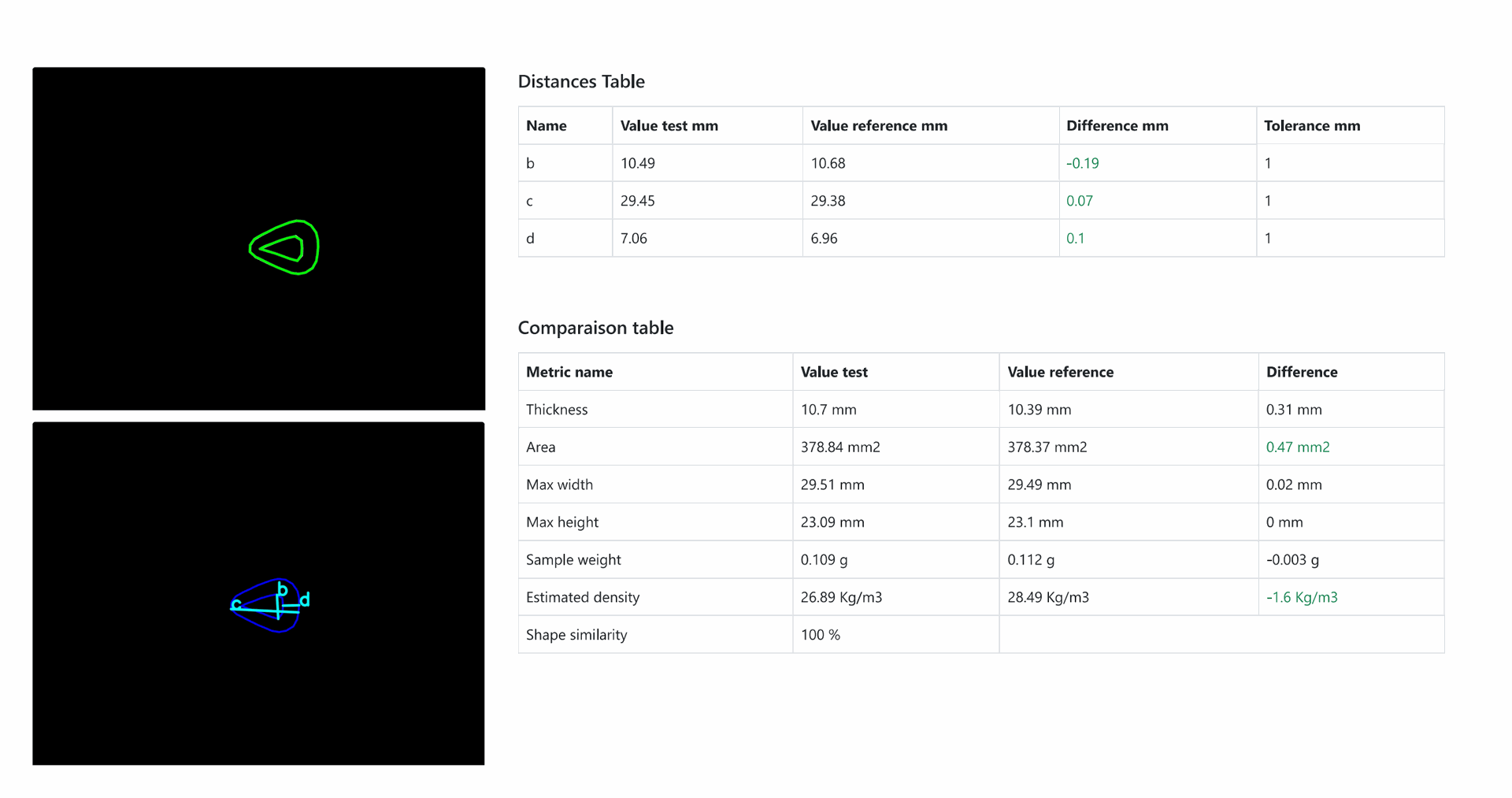

Gaskets

Implementing PROFIMAT for gasket quality control, optimizes production efficiency and ensures consistently high-quality seals, reducing rework and enhancing overall product reliability.

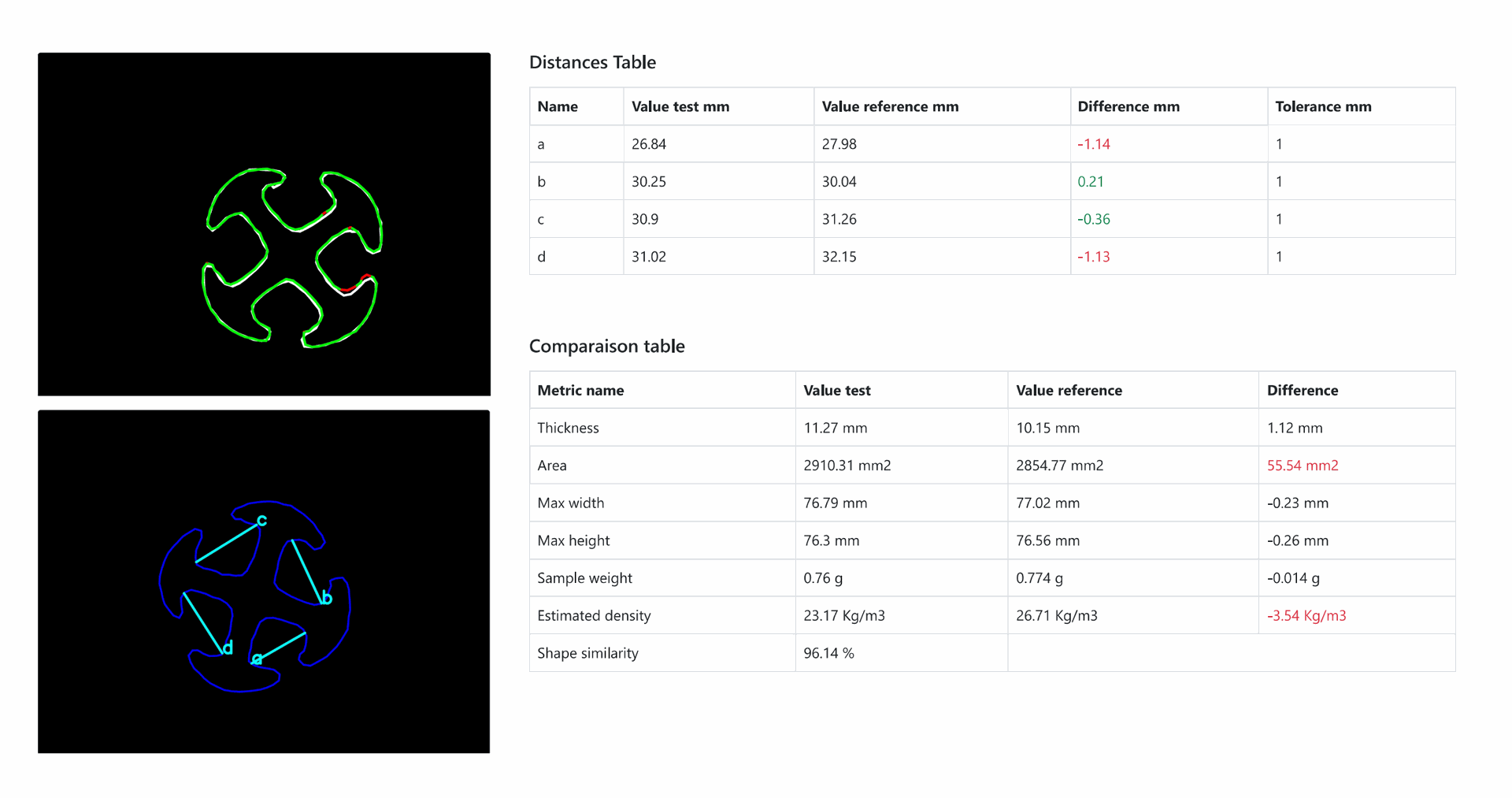

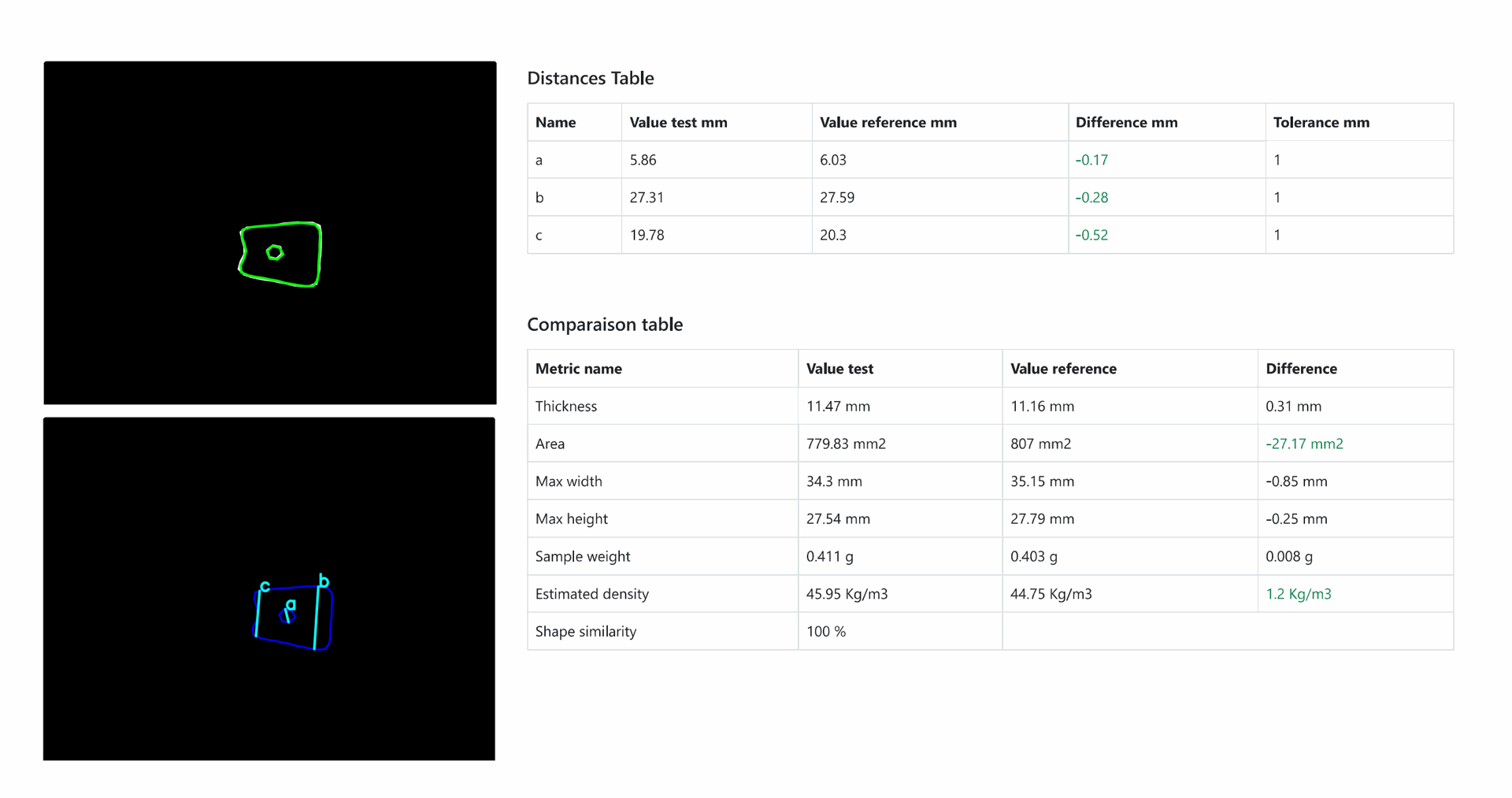

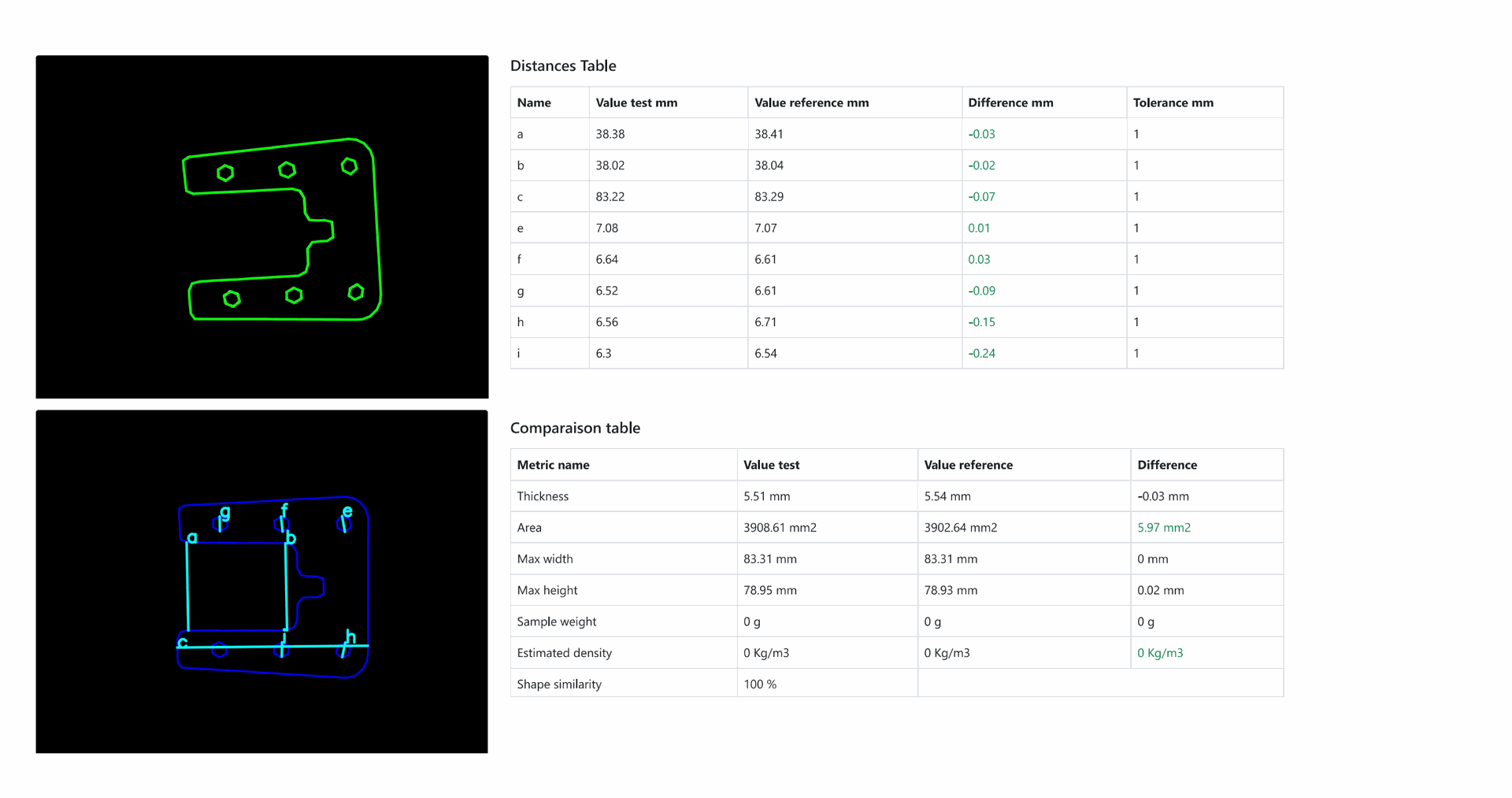

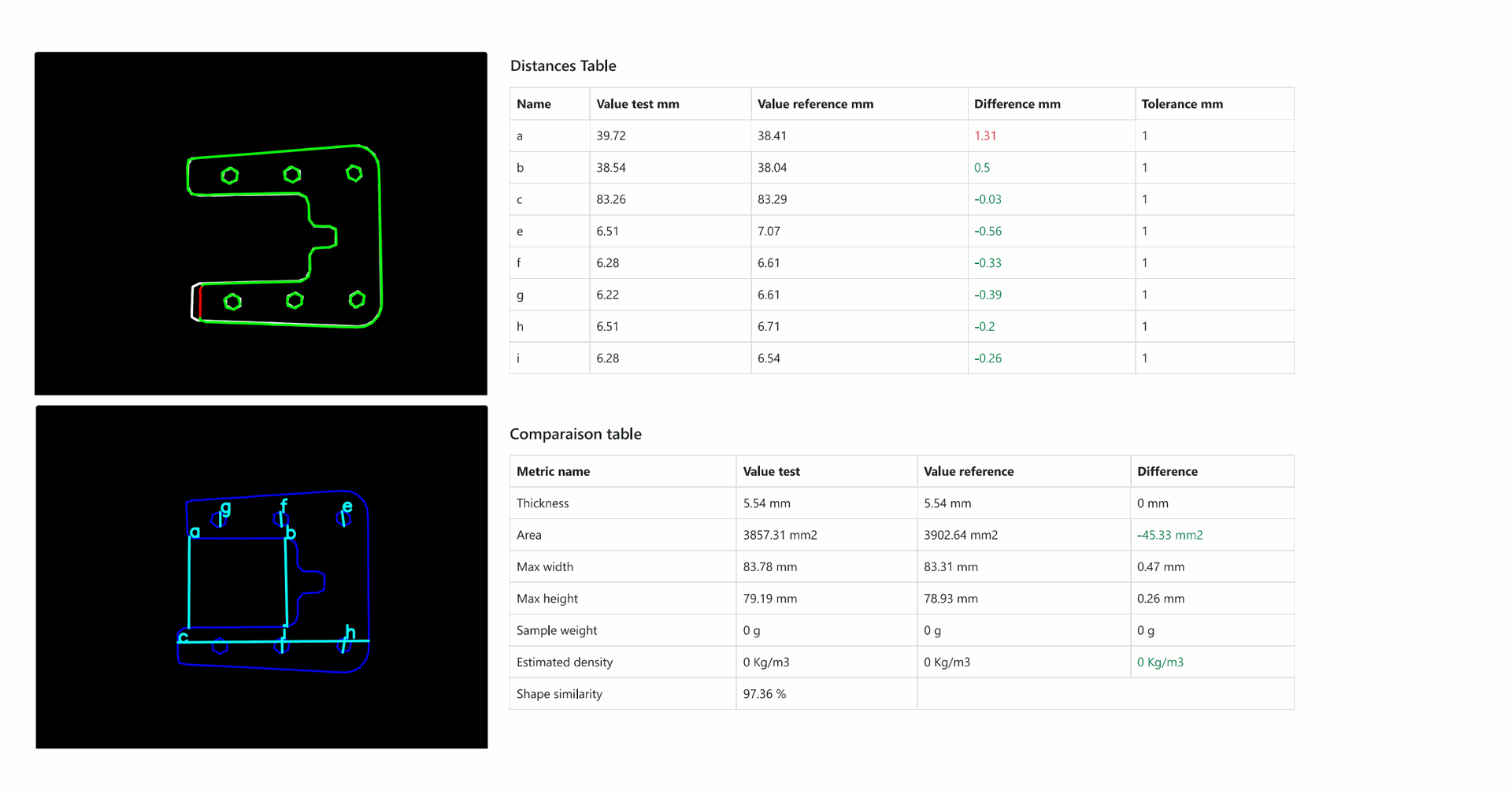

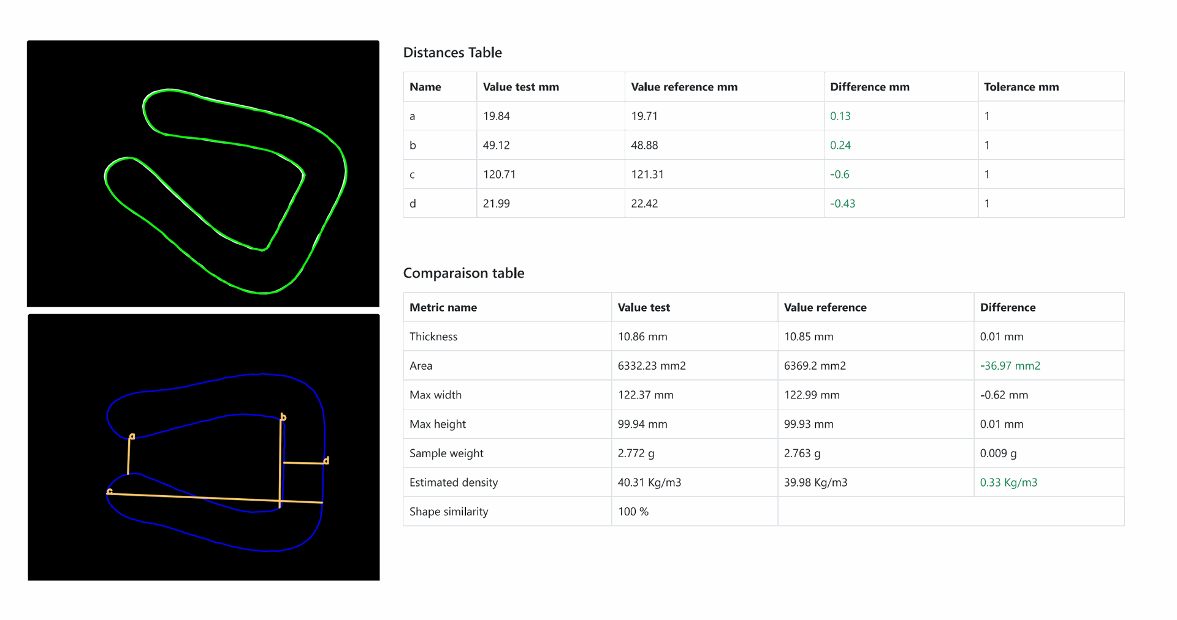

Mechanical parts

A custom solution was developed to not only control the shape and dimensions but also to calculate thicknesses in multiple points.

Plastic products

PROFIMAT can be integrated with your system to play an important role for your OEE calculation by counting produced pieces and defects.

Our solutions are Trusted by Market Leaders

Top companies uses PROFIMAT to automate and digitize quality control

Protect you brand by using PROFIMAT for your quality control.

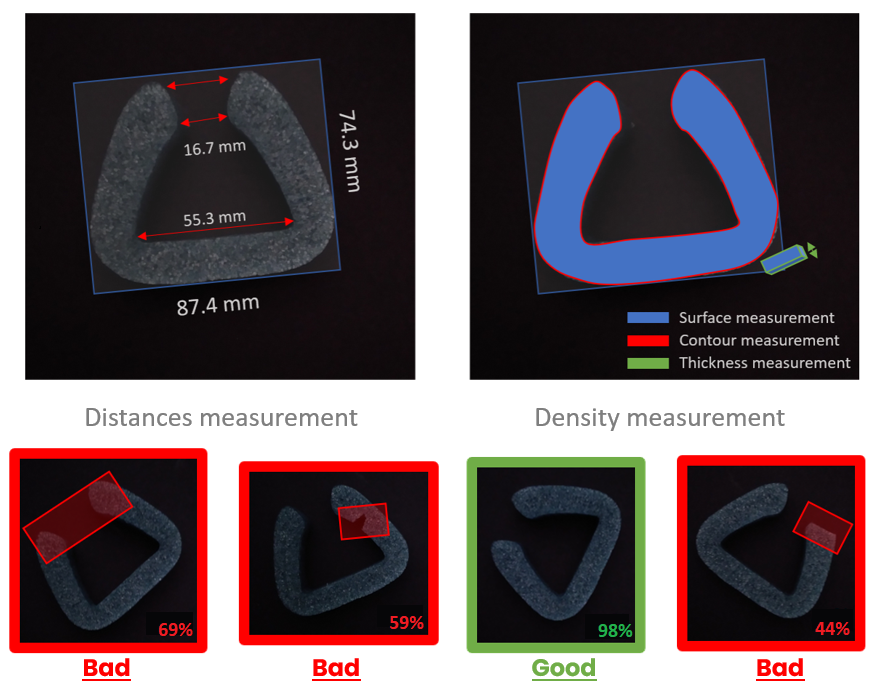

SET UP YOUR REFERENCE

Use only one part to create your product reference and set up your reference dimensions.

PROFIMAT is designed to be a reliable and efficient way to empower your quality control process and take it to the next level.

By using a single reference product and configuring the dimensions to be checked and the tolerances only once, PROFIMAT will be able to use this reference to control your parts in a completely automatic manner.

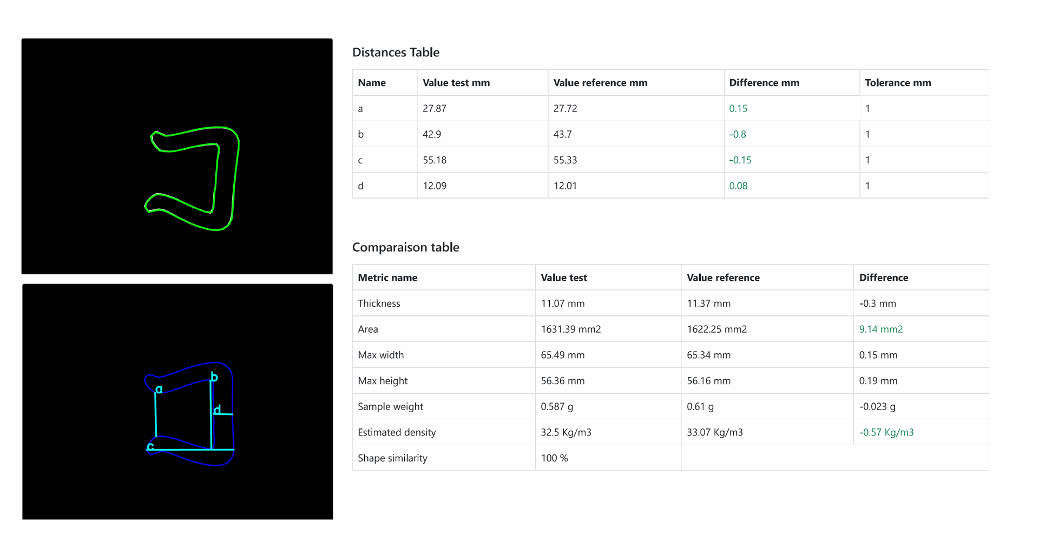

ONE-CLICK TO PERFORM A TEST

To start a new control test on your profiles, all you need to do is specify the name of your product and click on the start test button.

PROFIMAT provides you with detailed reports of your test ready to be exported and sent to your customer to maximize trust and reliable deliveries.

Experience significant time savings by automating quality control and allowing you to allocate resources more efficiently.

WHY USE PROFIMAT

Save your time and your money

Automated quality reports

Improve quality and reduce clients returns

allocate resources more efficiently.

Interested? Book a demo now.

Protect your brand by providing flawless products.

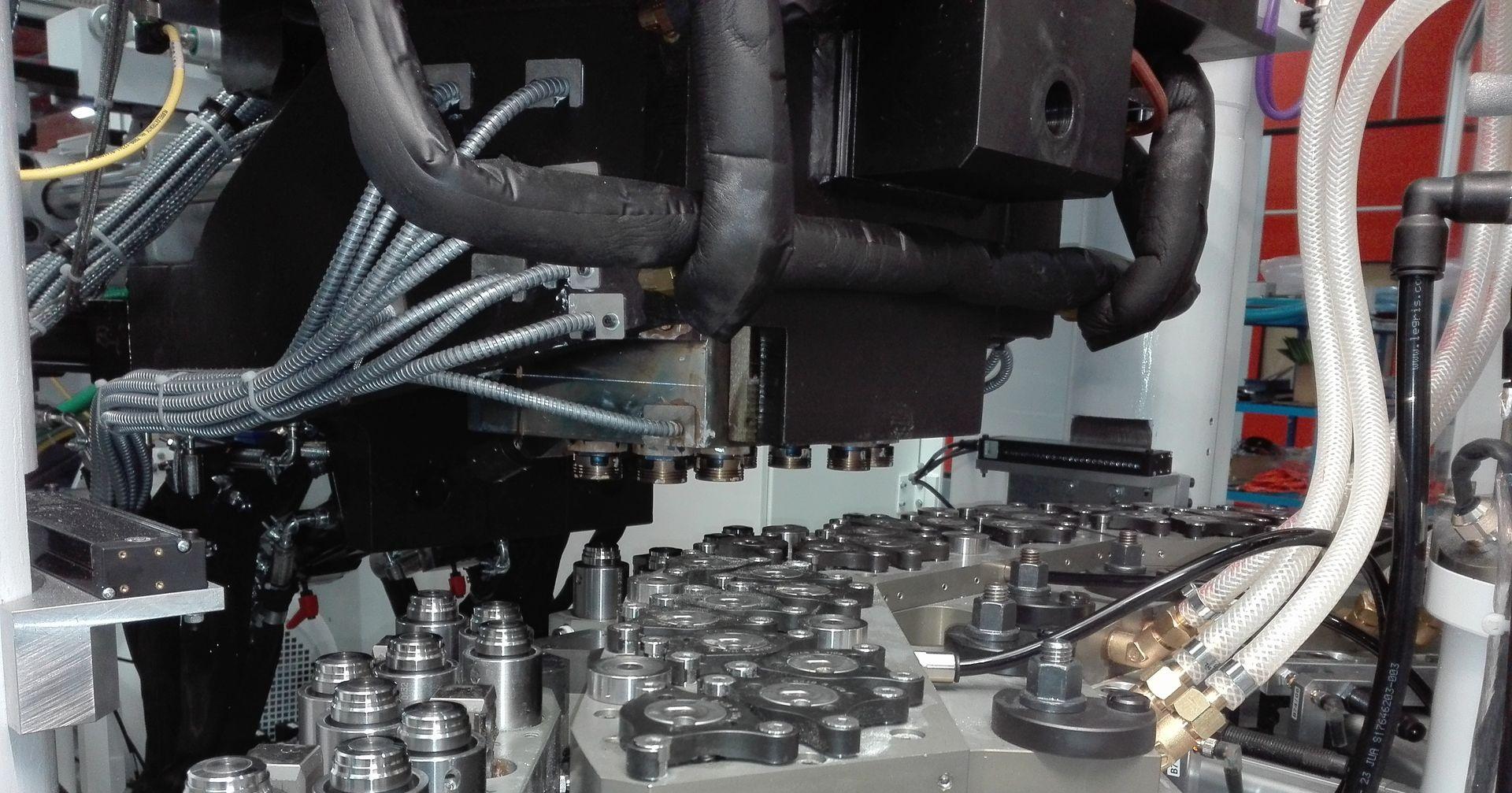

PROFIMAT IN ACTION

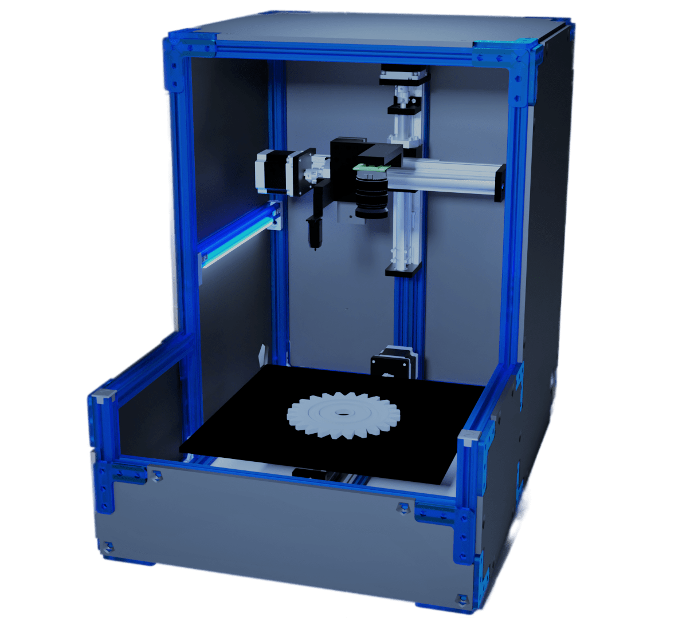

A TAILOR-MADE MACHINE FOR EVERY NEED

PROFIMAT is not a single device for everybody but a unique device for everyone. Tell us what you need, your specifications, and your budget and we'll take care of the rest! We guarantee you a result that meets your expectations and an unbeatable price. Questions?